The inline frame game hasn’t been the same since the introduction of Solá Equipment. The mind behind the concept is Kyle Solá, a sports equipment designer that’s been working behind the scenes in blading for years helping leading companies with product improvements, and of course is now spearheading the Them Skates 909 project with Jon Julio. We’ve long been impressed with his exacting reputation and precise components, so when preparing Issue #25 we worked with photographers Dean Bradley and David Sizemore to put together this Q & A sharing more insight on his current products and plans for the future. Check it out.

* * * *

Kyle, tell us where the idea for the aluminum frame came from.

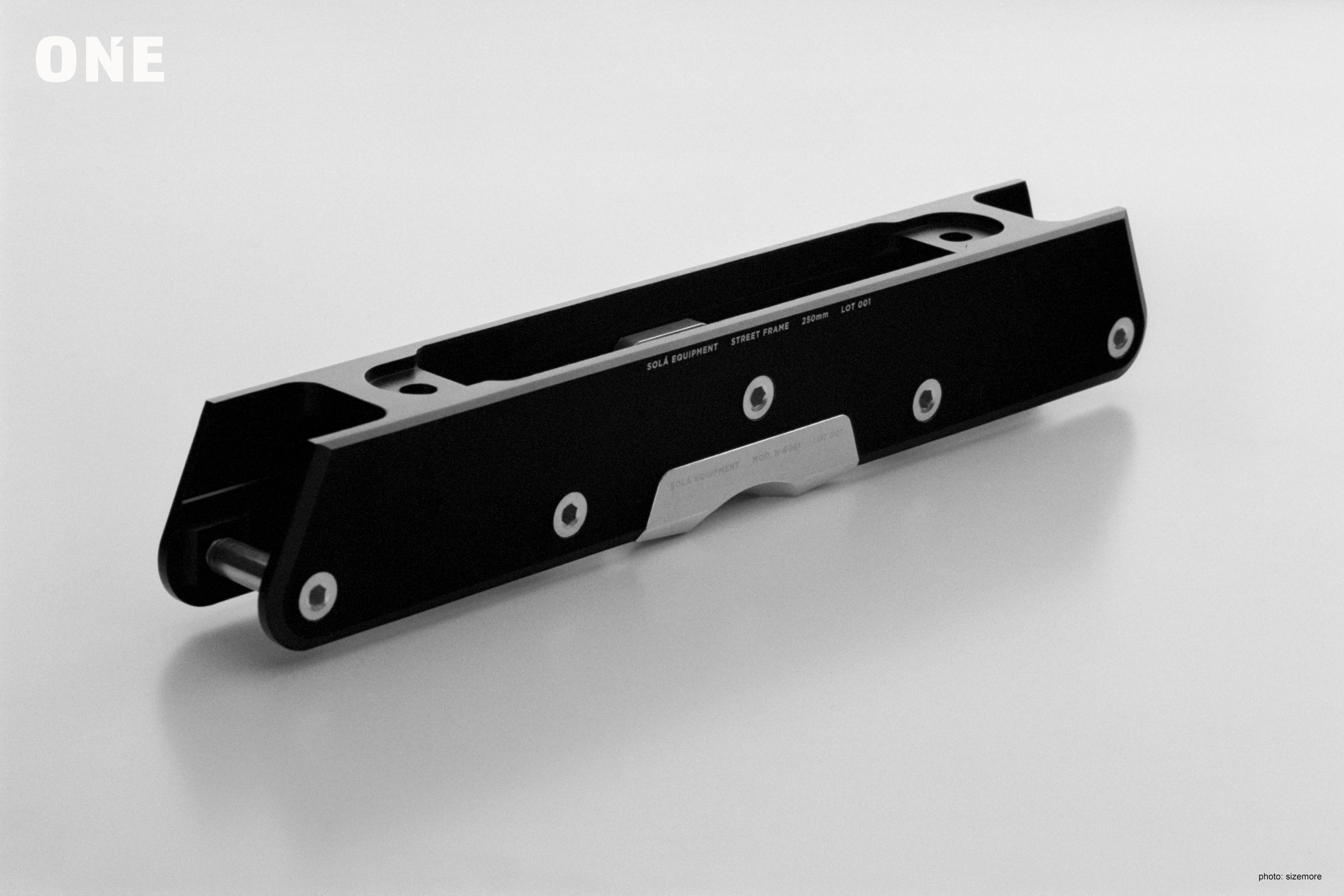

The concept for the aluminum frame was built from a series of conversations with Dominik Wagner, regarding the optimal flat-rocker frame that could be used to skate both street and park. We knew the grinding and power transfer benefits of aluminum from skating larger aluminum frames, but there was nothing on the market with the proportions of a classic street skating frame, that would allow a low-to-ground ride that we loved from plastic frames at the time.

How does that relate to the one-off samples that Joe Atkinson and Dominic Wagner had been seen skating for sometime before your release?

The first samples were made from a solid block of aluminum, so there was not an option to remove the h-blocks for a plastic option. The first three frames were made for myself, Joe and Dominik. Each frame was made specific to each of our specific-desired wheel sizes and wheel bases. We initially tried 65mm and 72mm versions, but in the end we were all going down to 58 or 60mm wheels in order to get a lower riding height, as we found the speed even more than sufficient with the smaller wheels.

What characteristics should someone expect from a pair of your frames?

The frames skate and grind very fast. Because of the stiffness, there is a haptic feeling of feedback from the frames while grinding, something that isn’t felt with normal plastic frames. The thin walls add space to the soleplate and allow you to grind closer to the center of your foot, making it easier to balance on rails. The feeling can be described as precise and performance oriented, as opposed to bulkier and softer plastic frames.

How about the various h-block options and the available materials, have you done all you plan to in that space, or are there more options to come?

The H-block has been a great space to experiment. The ability to transfer my professional experience in additive manufacturing (3D Printing) allows me to have a different approach to experimentation, specifically in regards to h-blocks and soleplates. This, tied to my close relationship with so many talented skaters, allows us to try and test new ideas quickly and without a large investment. That said, there are certainly a lot of ideas and current experiments in the works or being tested that have not been seen publicly yet. Design, development, and use are very much a circular process.

Not long after your debuted your frames, several other companies brought products to market quickly that appear to be at least influenced by some of your decisions. How does that make you feel?

The influence to other brands in the market was inevitable, especially if you see how well skaters like Joe Atkinson, Dominik Wagner, Maxime Genoud, Sascha Simms and Ivan Narez have been skating them.

It is disappointing when a product is so closely imitated, but I do think customers will realize the difference in quality and customer focus; I’m optimistic as there is a desire within the community to support skater-owned brands.

What is your background? How did you end up working in industrial design, and why do you live in Switzerland?

I grew up street skating in New York and have always been fascinated by the sports equipment I have used, and how it was designed and developed to either house, protect, shape or enable the human body.

After high-school, I chose to pursue an education in Industrial Design at Pratt Institute in Brooklyn, New York City. Upon graduating, I went to work on the design and development of precision surgical instruments and performance equipment for Olympic swimmers and World Champion Ironman triathletes. Four years ago I began research and development into Additive Manufacturing for an eyewear startup, and have been living between Munich, Germany and Zürich since.

Are there any unexpected revelations you had while designing the frame? Will there be future iterations that build on any feedback or ideas you’ve had since releasing this version?

The incredible support from the community. My approach is to work in a way in which a feedback loop between myself, customers, and professional athletes can inform important considerations for product developments, options and improvements. I have been fortunate to be surrounded by so many people who have been generous to share their experiences with me, which will be taken into account for future production runs.

Your frame is primarily skated flat rocker, from what we can tell. Is that how you intended people to use it? What are other setups you’ve seen people use on your product? Do you have strong thoughts on rocketing in general?

Yes, it is primarily skated flat-rocker, as it is designed for this. Geometrically, the h-block is positioned lower than the axle centers, which significantly reduces the potential of wheel bite. That said, people are skating them anti-rocker, there is a specific 3D-printed anti-rocker H-block available. Additionally, I have made a custom tri-rocker H-block for myself, and some special freestyle and anti-rocker setups for friends here in Switzerland.

I feel that wheel setups are very-much dependent on personal preference and the type of terrain you skate, I am glad to be able to use my frames as a platform to provide more choices for people to experience skating in different ways.

Were you influenced at all by the Wizard Frame and the work Leon has done in the space?

Leon is absolutely an inspiration. I revere his approach to frame design and manufacturing. A big shoutout to Rob G for being so kind in connecting me to Leon back in 2014. After first meeting via Skype, Leon was kind enough to connect me with his frame manufacturer, who made the first set of three frames for Dominik, Joe and myself in 2015.

Would you ever consider offering a custom frame option so people could order frames to their exact specifications?

Yes. I work professionally on athlete specific equipment, but current costs are too high to offer such a service at a reasonable price that makes sense for both customer and business. It is certainly something that will be more accessible in the next few years. At the moment, I am trying to make informed product decisions, and provide the necessary materials to customers so they can educate themselves on the basics of frame sizing and geometry.

Working / Photo: Bradley

What are the most exciting things happening in skating right now?

Personally, I am most excited about having a platform to foster creative collaborations with skaters, designers and artists and brands that I admire.

What should readers expect to see from Sola in the next twelve to fourteen months?

Thoughtful product and meaningful collaborations. I only plan to push into spaces where I feel potential has not been met, or a specific need is missing. I can’t go into more detail than this, but next year is going to be exciting.

See this and more in Issue #25. Order yours HERE.

[The END]

Photos by Dean Bradley and David Sizemore